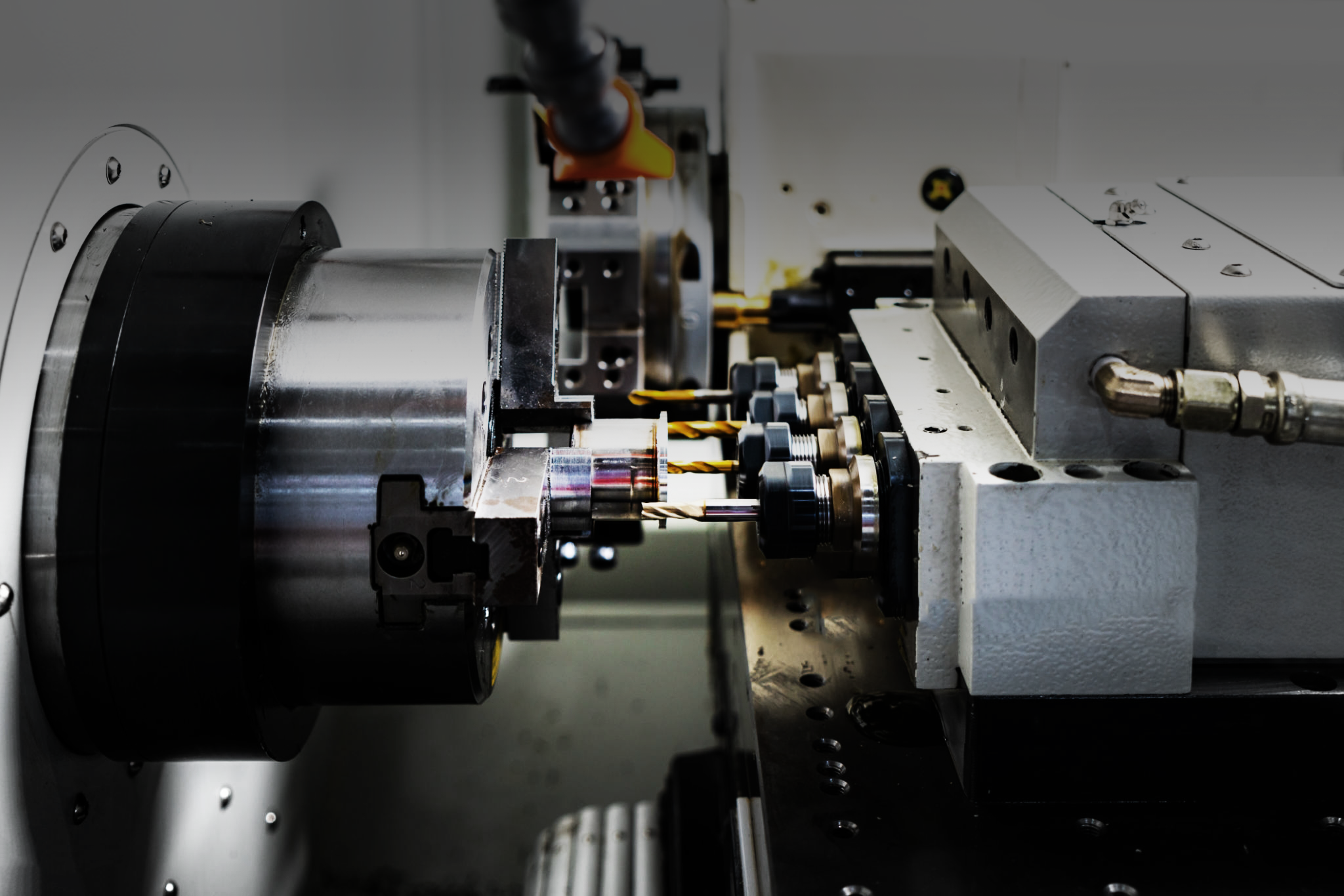

Always one step ahead of the competition

Digital upgrade of production, products & processes

Data acquisition | Data processing | Data integration | Data analysis

Holistic networking of machines along the value chain

Intuitive data exchange between man and machine

make it. simple. plug & play.

The digital factory

In the smart factory of the future, all machines, plants and systems are holistically networked with each other by sensors in order to optimally exploit all productivity potentials along the value chain.

Modular in.hub retrofit concept in 4 steps

Data acquisition by means of coordinated sensor technology

Data processing using the IoT gateway master module

Data networking of existing plant, machine and process levels

Data integration in cloud or server-based IT systems

Application scenarios

Performance promise of in.hub

Our collaboration with you

We have already implemented numerous digitization projects for pretty much every industry. Whether very old productions with machines that are in their prime or very modern and fully automated manufacturing - there is nothing that we have not already seen.

We have something for everyone: Newcomers to the field of digital factories are welcome to request the in.hub all-round carefree package. This includes a comprehensive analysis of your company's current situation, the creation of a concept for your digitization project, research and selection of the appropriate sensors and accessories, the corresponding in.hub hardware and software, installation on site, and subsequent analysis and processing of the data you have collected. You have one contact person for the whole project.

No matter if you are a newcomer in the field of digitalization or already a professional - at which point you want to work with us, you decide! Cross-entry is possible at any point.

Your benefits with in.hub

predictable

Better planning of annual targets

Early detection of anomalies and wear and tear

Predictive maintenance and servicing

reliable

Ensuring customer satisfaction by guaranteeing continuous quality standards

Stable processes

Production data in real time

transparent

Ensure comparability of processes

Insight into profitability of production

Data visualization

efficient

Avoidance of unexpected costs

Optimized and resource-saving processes and workflows

Reduced maintenance times and downtime costs

productive

No idle time for machines and employees

Decreasing reject rates

Increase in production due to higher machine utilization

Frequently asked questions

Can I also measure only at certain events, e.g. when the motor or pump is actually working?

Yes, this is possible. A trigger input is available for this, which can even detect speeds.

We are a software manufacturer for MES systems and often need machine signals for our evaluation at our customers. Are the in.hub products suitable for this?

Yes, we already have many customers from the software industry. Our products are designed so that any machine can be monitored. With our Software Development Kit (SDK), it is also possible to independently create connectors or apps to complement your own software.

I would like to display the recorded data transparently for my employees in production so that we can react more quickly to events together. What is the easiest way to do this?

If you already know what information and displays you want, we can easily display them in a live dashboard. Using a monitor that is connected to your company network, this dashboard can then be displayed anywhere. Typically at the workstation, in hallways or office areas. The dashboards can also be designed interactively.

Can I label and resell the products with my own brand logo?

Yes, we also offer our products as white-label, so that your own branding is possible. Contact us and we will explain the process to you.