in.hub news

What's new at in.hub?

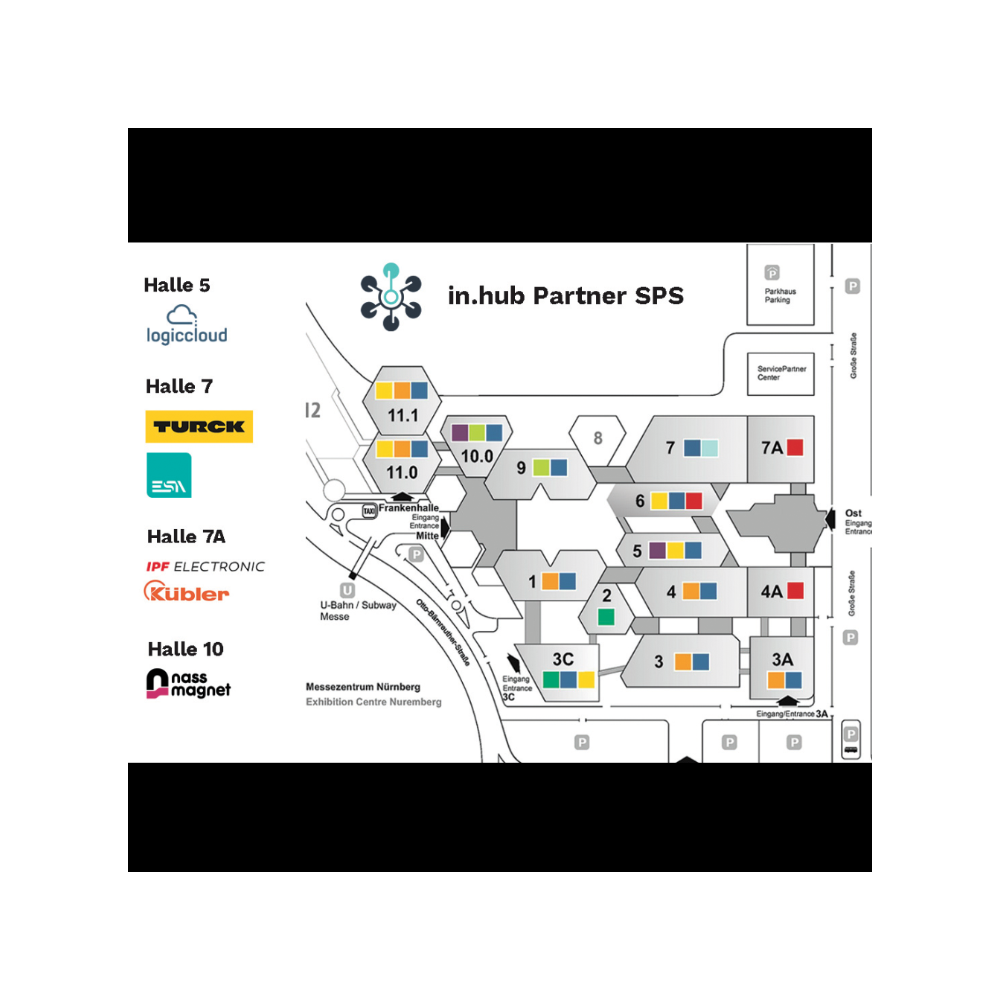

SPS 2025 is approaching – and our partners are showcasing what’s possible with in.hub!

This year again, our technology partners ipf electronic gmbh, TURCK, nass magnet Hungária Kft., Kübler Group, ESA Automation & Robotics and logiccloud AG will present exciting live applications built around in.hub hardware and software.

At their booths, you can experience how easily our solutions integrate into existing machinery – from energy and process data acquisition to IO-Link connectivity and AI-assisted edge programming. Our partners will demonstrate how efficiency can be increased, how valuable data becomes visible, and how digital added value can be created right at the machine.

👉 It’s worth stopping by:

All partner teams are looking forward to meeting you, exchanging ideas, and showing practical live demonstrations.

📅 25–27 November 2025 – SPS Nuremberg

Find our partners here:

📍 ipf electronic gmbh – Hall 7A, Booth 131

📍 TURCK – Hall 7, Booth 250

📍 ESA Automation & Robotics – Hall 7, Booth 350

📍 nass magnet Hungária Kft. – Hall 10, Booth 523

📍 Kübler Group – Hall 7A, Booth 506

📍 logiccloud AG – Hall 5, Booth 160

Let’s shape the future of industrial digitalization together – efficient, local and without complexity. 🙌

Add-on-Finanzierung: TGFS und SBG investieren weiter Wachstumskapital in in.hub

Nach dem ersten Investment investiert der TGFS Technologiegründerfonds Sachsen gemeinsam mit der Sächsischen Beteiligungsgesellschaft SBG erneut in die in.hub GmbH.

Mit der Add-on-Finanzierungsrunde in siebenstelliger Höhe stärken wir bei in.hub unsere Position als führender Anbieter von Plug-&-Play-IIoT-Lösungen für die Industrie.

Wir bauen mit dem Wachstumskapital insbesondere die Bereiche Academy, Services und Marktplatz weiter aus und treiben so unsere Mission voran, industrielle Digitalisierung einfach, lokal und skalierbar zu gestalten.

👉🏻 Link zur News bei TGFS

Wir sind zu Gast beim IO-Link Forum in Paderborn!

IO-Link Forum Paderborn: nass magnet & in.hub gemeinsam vor Ort

Am 13. November 2025 trifft sich die IO-Link Community im Heinz Nixdorf Museums Forum in Paderborn – und unser Partner nass magnet ist mit dabei!

Unter dem Motto „IO-Link als Schlüssel zur Modernisierung“ dreht sich alles um praxisnahe Lösungen, wie sich Anlagen effizient und zukunftssicher optimieren lassen.

Wir freuen uns, gemeinsam mit nass magnet vor Ort zu sein und unsere Applikationen rund um IO-Link, Condition Monitoring und lokale Datenverarbeitung zu zeigen.

Wie sich Sensorik, Aktorik und intelligente Gateways perfekt ergänzen – das erleben Besucher live am Stand von nass magnet.

📅 13. November 2025 | 09:00–16:30 Uhr

📍 Heinz Nixdorf Museums Forum, Paderborn

Praxisworkshop am 15.10.2025 beim Automatisierungstreff Heilbronn

Wir sind wieder dabei !

Ohne Cloud. Ohne Code. Ohne Komplexität.

Am 15.10.2025 beim Automatisierungstreff in Heilbronn – mit einem neuen Praxis-Workshop rund ums Thema Energie sichtbar machen. Lerne, wie Du mit unserer Lösung einfach Energieflüsse erfasst, analysierst und direkt Maßnahmen ableitest – ganz ohne Programmierung und ohne Cloud.

👉 Du entwickelst Deine eigene Anwendung, nimmst Hardware & App direkt mit und kannst sofort loslegen!

📅 Wann? 15.10.2025 von 09:00 – 17:00 Uhr

📍 Wo? WTZ-Tagungszentrum Heilbronn

✅ Warum teilnehmen?

✔️ Praxisnahe Einführung in die digitale Zustandsüberwachung

✔️ Hands-on: Digitalisierung zum Anfassen

✔️ Direkte Umsetzung in Ihrem Unternehmen möglich

Die Teilnehmerzahl ist begrenzt – sichere Dir jetzt 👉 hier deinen Platz!

Workshop „OEE, Condition Monitoring & Predictive Maintenance“

Maschinenstillstand? Nicht mit dir! – Workshop in Chemnitz 🚀

Am 09.09.2025 laden wir dich zum Praxis-Workshop „Maschinenstillstand? Nicht mit dir!“ nach Chemnitz ein.

Erlebe live, wie OEE, Condition Monitoring & Predictive Maintenance funktionieren – praxisnah, interaktiv und mit garantiert mehr als nur einem Aha-Moment. 😉

📅 Wann? 09.09.2025 von 09:30 – 14:30 Uhr

📍 Wo? in.hub Chemnitz

Die Teilnehmerzahl ist begrenzt – sichere dir jetzt deinen Platz!

Unser Podcast mit Derdack SIGNL4

🚀 IoT hautnah erleben

Im SIGNL4 Podcast verrät unser IIOT Senior-Partnermanager Christoph Müller, wie Alarmierung & Automatisierung in IoT-Projekten wirklich gelingen. Von Flutwarnung bis Lastspitzen-Management – praxisnah und auf den Punkt.

🎙️ Jetzt reinhören: Hier geht's zum Podcast

Viel Spaß beim Zuhören! 😊

TGFS invests seven-figure sum in in.hub GmbH

TGFS Technologiegründerfonds Sachsen has invested a seven-figure sum in in.hub GmbH in a Series A financing round. We plan to use the additional financial resources to expand sales and to further optimise our hardware and software solution. A platform for additional applications is also to be developed so that customers can easily obtain further valuable information and insights into their machines. In the future, the platform will also be made available to external developers via a commission model.

You can find the full article 👉 here

Unser Podcast mit SITEC und IoT Use Case ist nun online verfügbar

Wir haben uns mit unserem Partner SITEC zusammengesetzt und gemeinsam einen spannenden Podcast aufgenommen!

🎧 Thema: "Von Daten zu Mehrwert: Wie SITEC & in.hub die Digitalisierung im Maschinenbau vorantreiben."

In diesem Podcast erfahrt ihr:

✅ Wie Daten aus Maschinenprozessen effizient genutzt werden

✅ Welche Mehrwerte durch smarte Digitalisierungslösungen entstehen

✅ Best Practices und spannende Einblicke aus der Praxis

Holt euch wertvolle Tipps und erfahrt, wie digitale Technologien den Maschinenbau revolutionieren!

🎙️ Jetzt reinhören: Hier geht's zum Podcast

Viel Spaß beim Zuhören! 😊

We are guests at the Techtextile trade fair in Frankfurt!

From April 23 to 26, 2024, we will be a guest of our long-standing partner, update texware GmbH, at the Techtextile trade fair in Frankfurt!

Be sure to visit the stand (Hall 12.0, Stand E58) - there we will show you how effortlessly we can integrate textile machines of all ages into the software world of update texware GmbH.

✅ MES/BDE

✅ Business Intelligence

✅ Production control center

✅ ERP

✅ Goods inspection

Come and see for yourself how we are revolutionizing the textile industry with our smart solutions and what exciting innovations the future holds for technical textiles. You will be amazed! We are really looking forward to meeting you in person and discussing the digital topics of tomorrow together.

Click here for the tickets: 👉 https://visitortickets.messefrankfurt.com/ticket/en/shop_select.html

Chemnitz 2025: Kulturhauptstadt Europas – Unsere Stadt, unser Stolz!

Das Jahr 2025 wird ein ganz besonderes für unsere Heimatstadt Chemnitz – wir sind stolz darauf, Teil der Kulturhauptstadt Europas zu sein! 🌍✨

Unter dem Motto "C the Unseen" zeigt Chemnitz der Welt seine verborgenen Schätze, Kreativität und Innovationskraft. Als Unternehmen, das in dieser dynamischen Region verwurzelt ist, freuen wir uns auf ein Jahr voller spannender Veranstaltungen, inspirierender Begegnungen und internationaler Aufmerksamkeit.

Von Ausstellungen und Konzerten bis hin zu Festivals und Workshops: Die Stadt verwandelt sich in eine Bühne für Kunst, Kultur und Innovation.

👉 Hier geht's zu den Veranstaltungen: Chemnitz 2025 Programm

Gemeinsam machen wir Chemnitz 2025 unvergesslich. Seid dabei und entdeckt, was unsere Stadt alles zu bieten hat! 💙

Webinar „Energieintelligenz in Echtzeit

OHNE CLOUD, OHNE PROGRAMMIEREN, OHNE STRESS: ENERGIEMANAGEMENT INTELLIGENT UMSETZEN.

Möchtest du erleben, wie du dein Energiemanagement effizient und stressfrei auf das nächste Level hebst? Dann sei am 13. August 2025 bei unserem kostenlosen Webinar dabei!

Unser Experte Marco Neubert zeigt dir, wie du mit dem HUB-EN200 deine Energiemessungen ganz einfach in aktive Intelligenz verwandelst. Erfahre praxisnah, wie du Energieverbrauch, Lastspitzen und außergewöhnliche Ereignisse in Echtzeit erkennst, intelligente Alarme in deine Prozesse integrierst und frühzeitig Anomalien entdeckst.

Du bekommst konkrete Praxisbeispiele aus Zerspanung und Textilproduktion sowie einen spannenden Ausblick auf Predictive Maintenance und weitere energieeffiziente Maßnahmen.

📅 Wann? 13.08.2025 von 10:00 – 10:45 Uhr

📍 Wo? Online via Microsoft Teams

✅ Warum teilnehmen?

✔️ Sofort nutzbare Impulse für dein Energiemanagement

✔️ Praxisnah und verständlich erklärt

✔️ Direkte Anwendung in deinem Unternehmen möglich

Die Teilnehmerzahl ist begrenzt – sichere dir jetzt 👉 hier deinen Platz!

Our podcast with Hans Turck and IoT Use Case is now available online

In this podcast we explain the first joint use-case for control cabinet monitoring with Hans Turck. Together with Madeleine Mickeleit and Klaus Ebinger we discuss challenges and opportunities for the automation industry and show how our siineos operating system and IIoT platform will add great value to Hans Turck hardware in the future.

Listen to the podcast here.

Help! It's Christmas time.

MERRY X-MAS AND A HAPPY NEW YEAR!

Trade fair kick-off for 2023 at all about automation in Hamburg

Let's go into the new Meesjahr 2023!

From 25.01.2023 - 26.01.2023 you can see us live and in color at booth OG-213 at the all about automation in Hamburg live and in color.

- Powerful and robust hardware for the implementation of IIoT projects

- Software siineos for the digitalization of machines, plants and processes

- App MaDoW for monitoring downtimes and productive times of machines and plants

Lecture by Christian Groß

Wednesday, 25.01.2023 | 14:20 h | Talk Lounge

Status quo IIoT - Is the subsequent digitization of a machine possible on one's own in 2023?

Make a note of it already now:

27.09.2023 – 28.09.2023 | aaa in Chemnitz

Tutorial series on Youtube (German)

We are happy that we have now put the first 6 episodes of our tutorial series on siineos online! 🚀👨💻🌐

In our previous videos, we have covered a variety of topics - from setting up the time zone 🕖 and the network to the firewall module and various functions such as measurement value processing. We also showed how to visualize measured values 📊 and gave many other useful tips and tricks that will help our users to exploit the full potential of siineos.

And that's just the beginning - in the coming weeks and months, we'll be covering many more interesting topics that will help you realize the full potential of siineos. Whether siineos is used in production, warehousing or other areas - we have tips and tricks that will save you ⏳ time and 💸 costs.

➜ 🎬 👍🏻✅

We invite everyone interested to watch the first 6 episodes of our tutorial series (in German only) and feel free to send us your feedback. We would really appreciate your comments and likes to know what you liked the most and where we can improve. 💡

Link to the Youtube Playlist:

September 2023 | in.hub at the aaa Chemnitz

Of course, we cannot be missing in Chemnitz!

We will be exhibiting at booth 1-453 on September 27 and 28.

We will show you our retrofittable hardware and software for your smart factory. The software siineos for the digitalization of machines, plants and processes as well as the powerful app MaDoW for the monitoring of downtimes and productive times of machines and plants.

But that's not all!

On Sept. 28, there will be a presentation by CEO Christian Groß on the topic of "Status quo IIoT - is the subsequent digitization of a machine possible on one's own in 2023?"

Free tickets are available here

Technical Committee of the Gesamtmasche - Online Event

On April 17, 2024, the Technical Committee of Gesamtmasche will meet for its spring meeting. Then everything will revolve around the question:

"What supports small and medium-sized textile and clothing companies in achieving their sustainability goals?"

In its spring edition 2024, the Gesamtmasche Technical Committee will present solutions that are particularly suitable for the textile and clothing industry, which is characterized by small and medium-sized enterprises.

Register free of charge using the link in the event and take part online! 👇🏻

Review of the successful siineos Partner Days 2024: Shaping the future together

On 25 and 26 September, we welcomed numerous machine builders, OEMs, software and service providers to the siineos Partner Days. Two days full of innovation, inspiration and exchange about the future of digitalisation in the machine world! 💡

The focus was on our vision for 2025, exciting product ideas, new functions and apps, as well as inspiring presentations by our partners and the many ways in which we can develop new digital business models together. Collaboration with our partners is the key to making machines and products future-proof - and the response was overwhelming!

Experience the highlights of the event and immerse yourself in the atmosphere of our aftermovie:

We are already looking forward to the sequel - together we are taking the next step into the digital future! 🙌

Praxisworkshop am 09.04.2025 beim Automatisierungstreff Heilbronn

OHNE CODE, OHNE CLOUD, OHNE STRESS: MASCHINEN DIGITALISIEREN LEICHT GEMACHT.

Möchtest du erleben, wie einfach und schnell sich Maschinen digitalisieren lassen? Dann laden wir Dich herzlich zu unserem Praxis-Workshop beim Automatisierungstreff in Heilbronn ein!

Hier erfährst Du aus erster Hand, wie Du mit unserer Lösung ohne Programmierung und in kürzester Zeit Transparenz über Deine Maschinen und Prozesse gewinnst. Egal ob Neumaschine oder bestehende Anlage - Du lernst, Sensoren über IO-Link, Modbus oder digitale Schnittstellen anzubinden, Daten in Echtzeit auszuwerten und direkt in Steuerungen zu integrieren. Zusätzlich gibt der Workshop wertvolle Einblicke in Predictive Maintenance, digitale Geschäftsmodelle und erfolgreiche Praxisbeispiele aus dem Maschinenbau.

Das Besondere: Du entwickelst Deine eigene Lösung, nimmst Hardware sowie App direkt mit und kannst sie sofort im Unternehmen einsetzen!

📅 Wann? 09.04.2025 von 09:00 – 17:00 Uhr

📍 Wo? WTZ-Tagungszentrum Heilbronn

✅ Warum teilnehmen?

✔️ Praxisnahe Einführung in die digitale Zustandsüberwachung

✔️ Hands-on: Digitalisierung zum Anfassen

✔️ Direkte Umsetzung in Ihrem Unternehmen möglich

Die Teilnehmerzahl ist begrenzt – sichere Dir jetzt 👉 hier deinen Platz!

7th Saxon Automation Day | Lecture on increasing productivity in medium-sized companies

Christian speaks on the topic at the 7th Saxon Automation Day of the Innovation Network Mechanical Engineering Saxony VEMASinnovativ:

📢Presenting ways to quickly and easily increase the productivity of existing machinery and equipment.

>> Keyword: RETROFIT

The associated benefits:

📌to exploit the maximum service life of existing machines and plants >> Keyword: Sustainability.

📌to minimize lengthy investment decisions >> keyword: resource conservation

📌to generate added value for customers through new business models >> keyword: competitive advantage

Event:

Day | Tuesday, 06.09.2022

Time | from 09:30

Place | Kraftverkehr Chemnitz