Monitoring of particle contamination in production

Permanent monitoring of the load from particles

Monitoring of sensitive areas with special requirements

Constant digital knowledge to ensure quality & occupational health & safety

make it. simple. plug & play.

Damage caused by particle contamination

Contamination by airborne particles can cause damage, both to human health and to machines and products. In manufacturing companies, different areas of the company are exposed to different levels of particle contamination. If particles contaminate machine elements such as a gearbox, the functionality of the machine is impaired and this can cause technical problems. In surface coating, for example, particle inclusions in the paint result in high rework costs, which costs time and money.

Controllable air purity is therefore a decisive factor in ensuring continuous compliance with occupational health and safety regulations as well as process and quality standards.

Methods of particle measurement

A conventional and frequently used method for particle measurement is the particle trap. Here, the adhesion of suspended particles on the trap surface is analyzed. This is done cyclically, i.e. at weekly or monthly intervals. The analyses are evaluated in a laboratory. This is time-consuming and expensive. Another proven method is air meters for measuring particle concentrations. On an installed measuring device, the locally measured impurities are shown on a display. Both methods have their justification, but are very costly and provide only past-related data.

In industry, however, the challenge is to record particle concentrations at several measuring points simultaneously and in combination with environmental parameters such as room temperature and air humidity and to evaluate them in real time in order to be able to counteract harmful conditions immediately from the outset. Ideally, the information can also be enriched with the products, customers, machinery, maintenance intervals and other information.

Particle measuring system pSYS

Real-time detection of particle concentrations

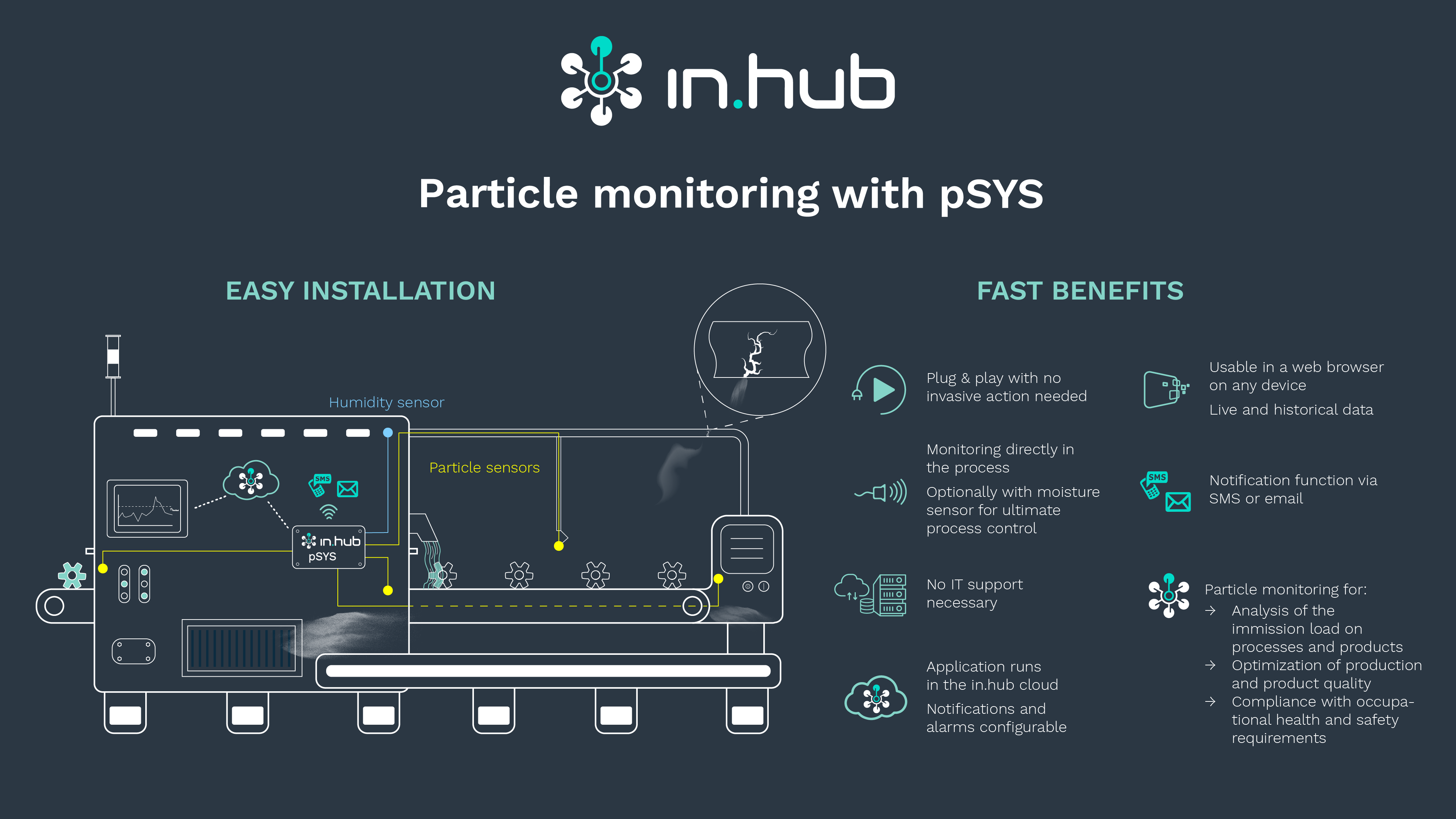

For near-real-time and seamless monitoring of particle concentrations, in.hub GmbH has developed the pSYS system for near-real-time monitoring of particle concentrations in cooperation with renowned customers and partners from the automotive industry as well as filtration and sensor technology.

The pSYS particle measurement system is a plug & play solution for the seamless recording and evaluation of concentrations of dust classes PM1.0 to PM10 at up to 5 measurement points. In addition, this holistic solution includes a temperature and a humidity sensor to ensure comprehensive information provision of all relevant parameters of the ambient conditions. Furthermore, helpful functions such as automated alarm and reporting are available. With customizable modules, interfaces can also be provided to in-house systems such as ERP, CAQ, building management software for HVAC data and many more.

Suitable products

Overall system pSYS

The complete out-of-the-box particle measurement system for easy plug & play installation.

Overall system pSYS

Software SIINEOS

The Linux-based operating system for IoT applications is already installed on all in.hub devices.

Software SIINEOS